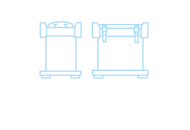

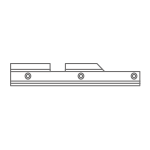

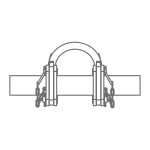

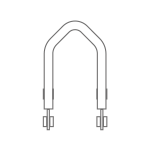

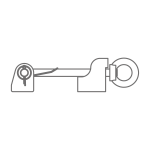

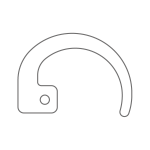

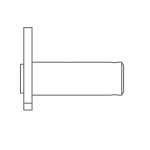

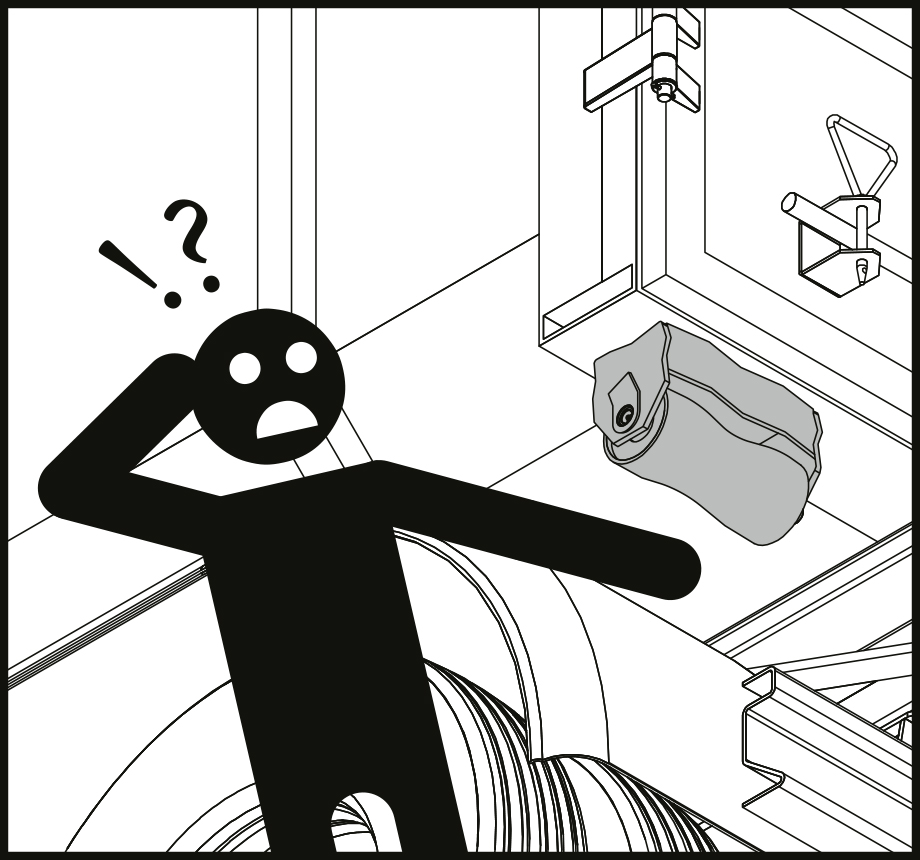

The problem with welded rollers

The problem with welded rollers

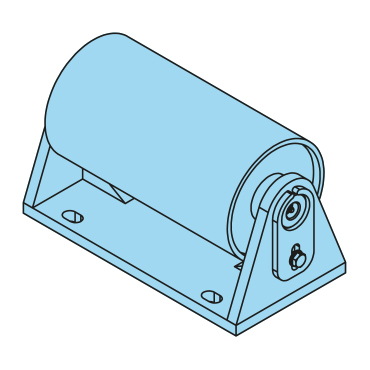

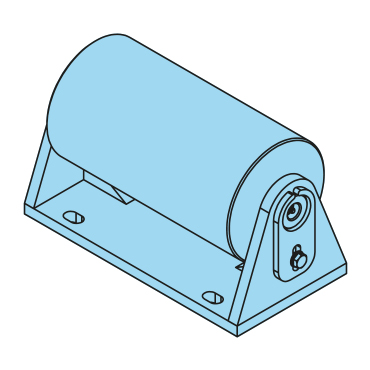

· typical recurring marks of wear and tear caused by uneven ground & one-sided placement of the container

· when worn, conventional rollers require costly and time-consuming replacement

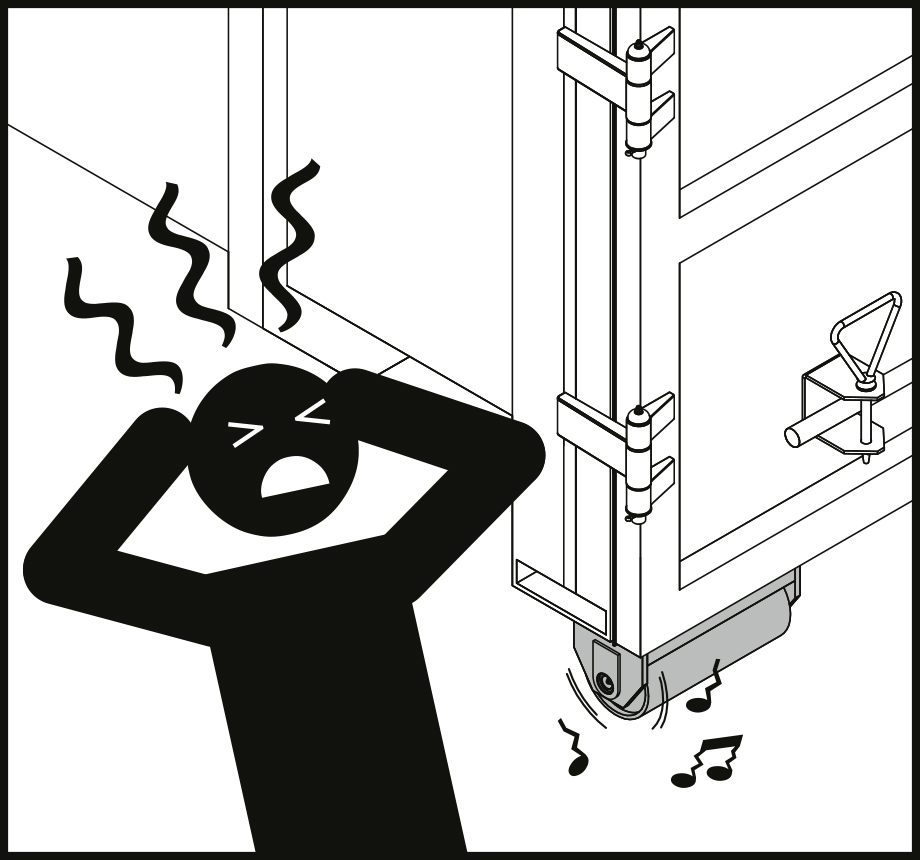

· if the brass bushings are not regularly lubricated, severe squealing may occur

· when worn, conventional rollers require costly and time-consuming replacement

· if the brass bushings are not regularly lubricated, severe squealing may occur

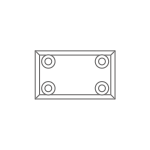

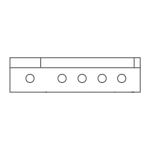

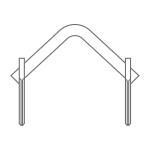

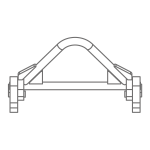

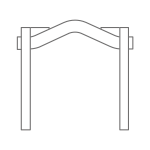

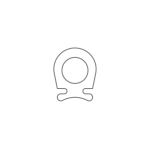

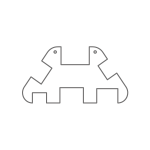

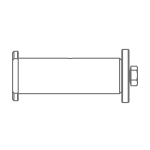

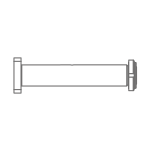

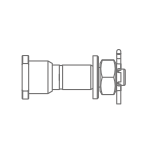

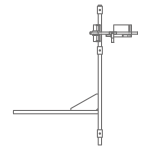

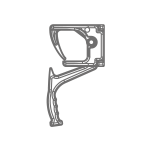

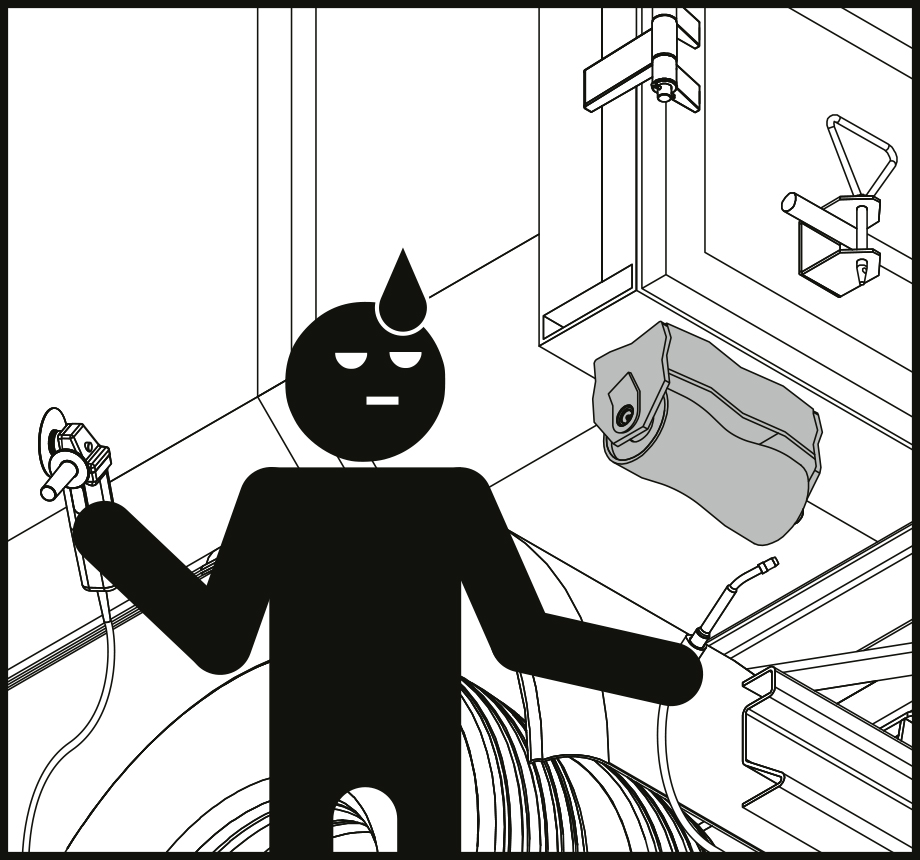

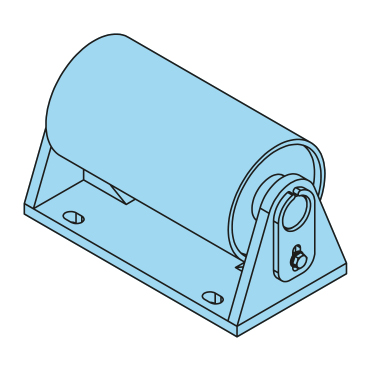

The solution: REWALD's Roller for bolted mounting

The solution: REWALD's Roller for bolted mounting

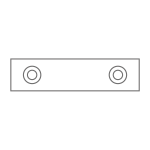

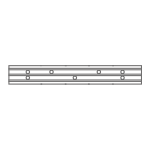

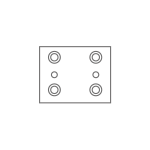

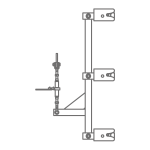

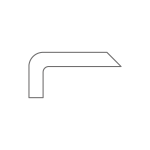

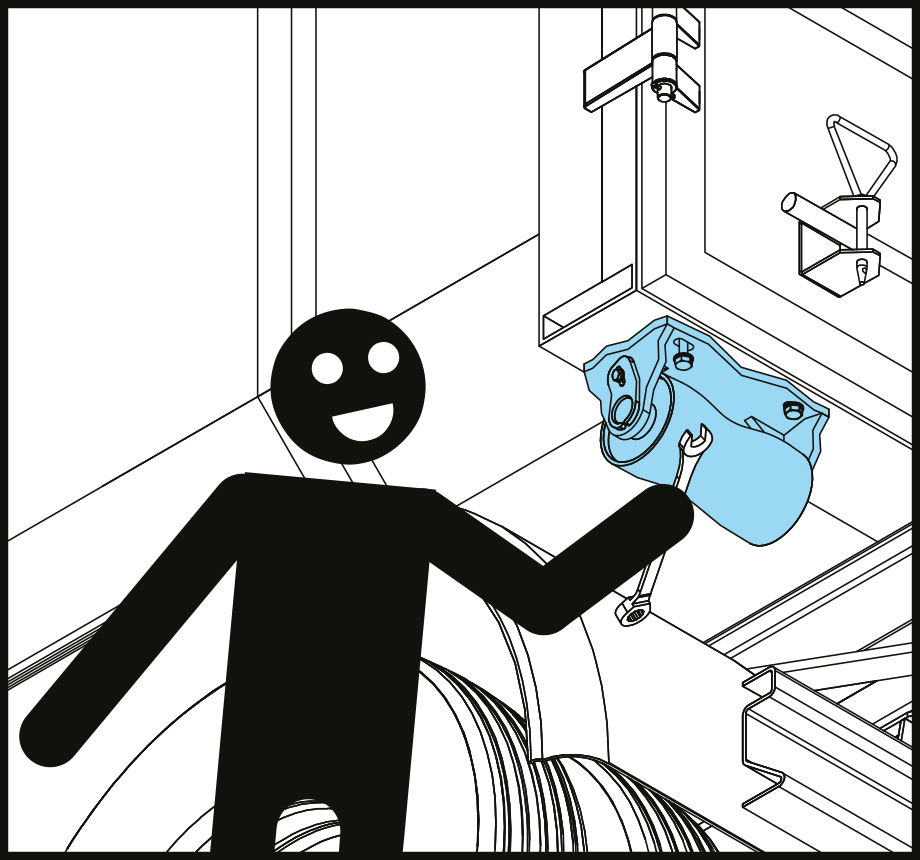

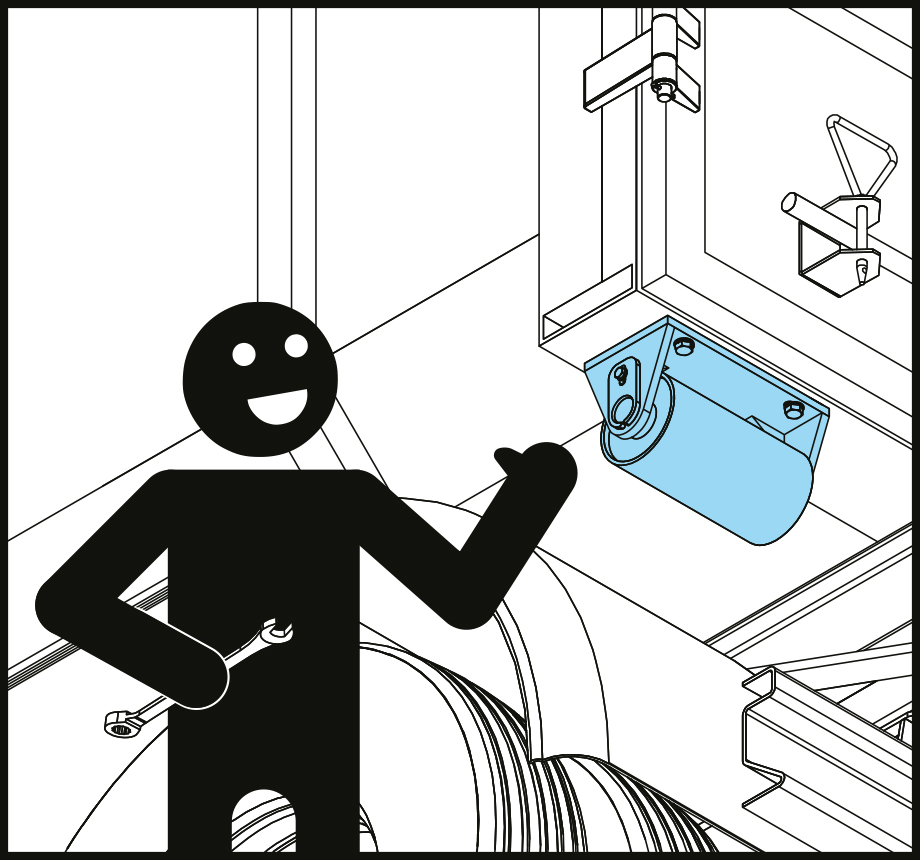

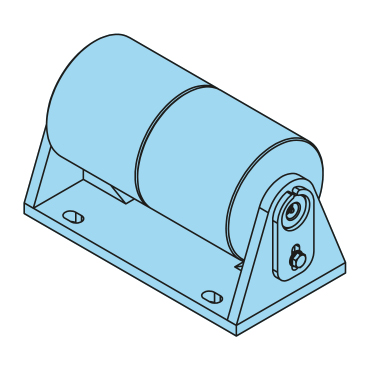

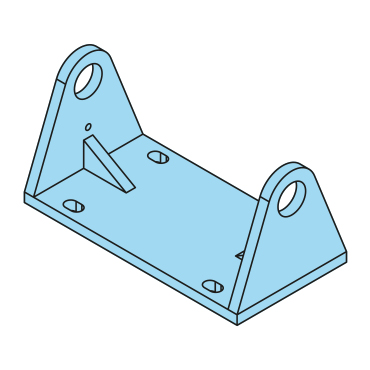

· the bracket is fixed only on the sides to allow quick replacement by loosening 4 screws

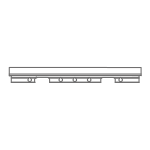

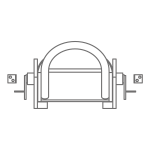

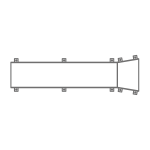

· load distribution over the entire axis by using a full sleeve tubing minimizes wear and tear

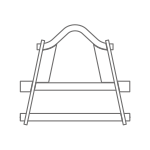

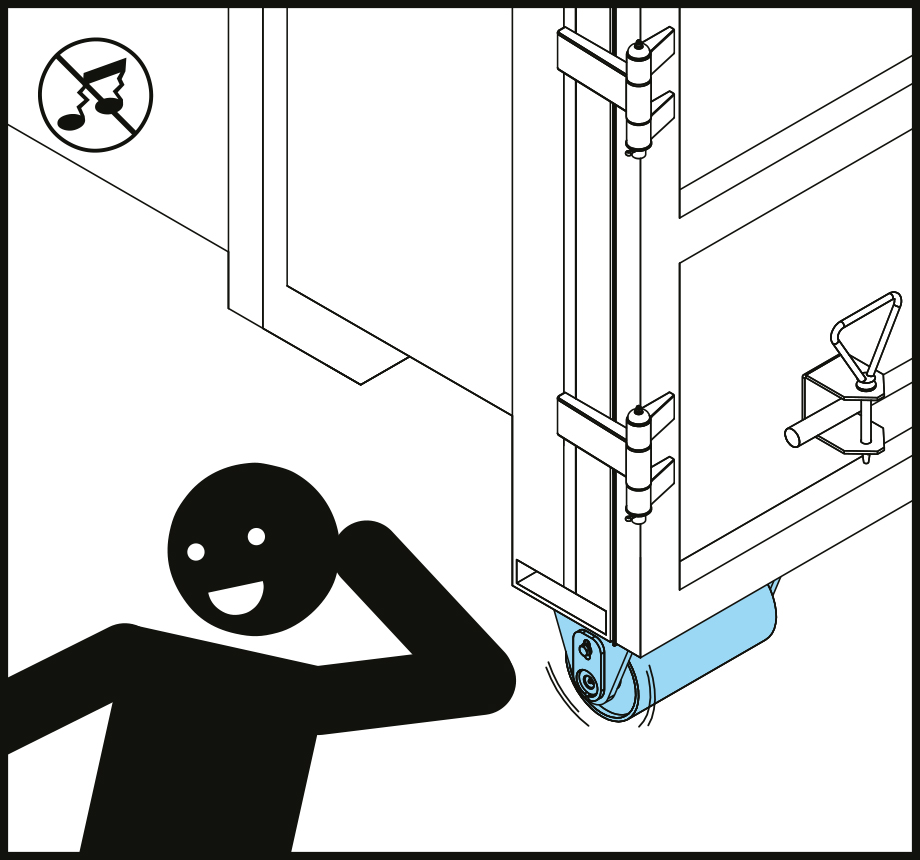

· reduced noise level by eliminating brass bushings

· very long lifetime of the bracket due to 15mm thick side plates

· a full sleeve inner tubing considerably reduces wear

· load distribution over the entire axis by using a full sleeve tubing minimizes wear and tear

· reduced noise level by eliminating brass bushings

· very long lifetime of the bracket due to 15mm thick side plates

· a full sleeve inner tubing considerably reduces wear